Choosing the right stone for your interior design style can enhance the aesthetic appeal, functionality, and overall harmony of your space. Here’s a guide to selecting the best stone types for different design styles:

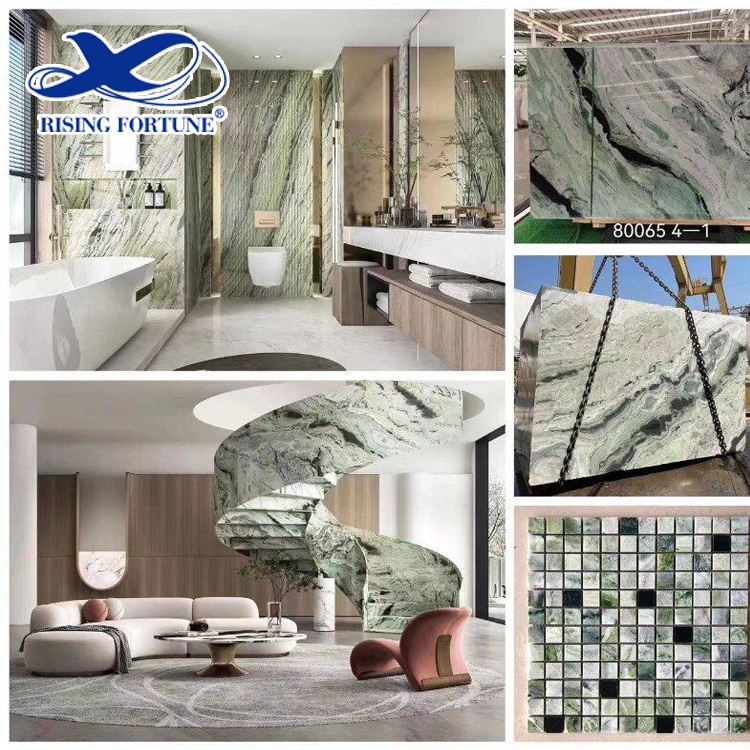

1. Modern/Contemporary Style

Key Features: Clean lines, minimalism, neutral tones, and sleek surfaces.

Recommended Stones:

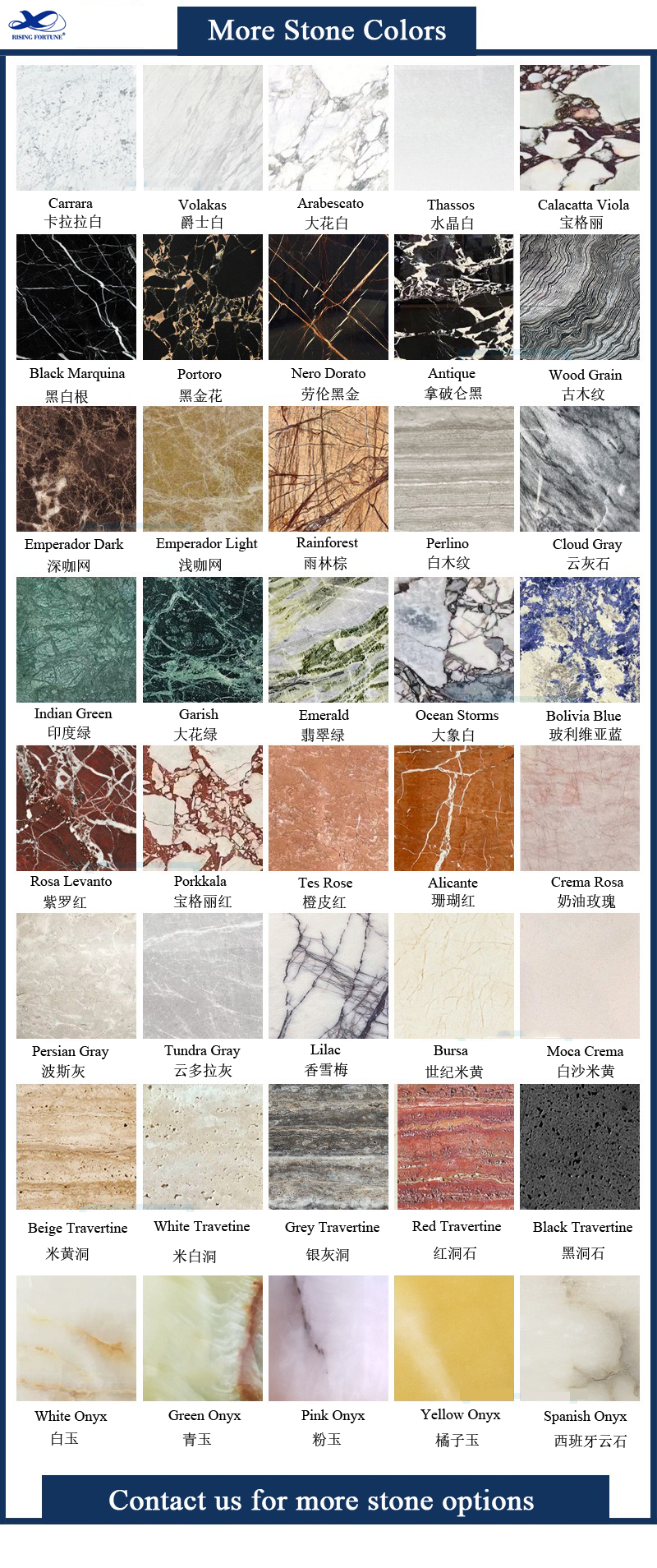

- Polished Marble (Carrara, Statuario, Calacatta): Adds luxury and elegance with subtle veining.

- Quartz (Engineered Stone): Low-maintenance, available in solid colors or marble-like patterns.

- Granite (Polished, Honed): Sleek and durable, ideal for countertops in neutral tones.

- Onyx: Translucent and dramatic, perfect for backlit feature walls or bars.

Best Uses: Countertops, flooring, statement walls, and fireplace surrounds.

2. Rustic/Farmhouse Style

Key Features: Natural textures, warmth, earthy tones, and a lived-in feel.

Recommended Stones:

- Sintered Stone: Textured and rugged, great for flooring and fireplace surrounds.

- Travertine: Natural pits and warm tones suit rustic kitchens and bathrooms.

- Limestone: Soft, matte finish that ages beautifully.

- Flagstone: Irregular shapes for patios, pathways, or feature walls.

Best Uses: Flooring, backsplashes, outdoor spaces, and fireplace facades.

3. Classic/Traditional Style

Key Features: Elegance, symmetry, rich details, and timeless appeal.

Recommended Stones:

- Marble (Carrara, Emperador, Nero Marquina): Classic veining for floors, countertops, and columns.

- Granite (Leathered or Brushed Finish): Adds depth without being too glossy.

- Soapstone: Smooth, matte finish ideal for traditional kitchens.

- Terrazzo: Vintage yet sophisticated for flooring and countertops.

Best Uses: Grand staircases, fireplace mantels, wainscoting, and formal dining areas.

4. Industrial Style

Key Features: Raw materials, exposed structures, and a utilitarian vibe.

Recommended Stones:

- Concrete (Polished or Stained): Mimics industrial lofts, great for countertops and floors.

- Basalt or Bluestone: Dark, dense, and durable for tabletops and flooring.

- Reclaimed Brick or Stone: Adds a weathered, warehouse-like texture.

- Black Granite: Sleek yet rugged for kitchen islands.

Best Uses: Countertops, flooring, exposed feature walls, and bar tops.

5. Scandinavian Style

Key Features: Light, airy spaces, natural wood, and simplicity.

Recommended Stones:

- Light Marble (Carrara): Soft veining complements neutral palettes.

- Quartz (White or Light Gray): Minimalist and easy to maintain.

- Pebble Tiles: Natural texture for bathroom floors or shower walls.

Best Uses: Kitchen countertops, bathroom vanities, and fireplace surrounds.

6. Bohemian/Eclectic Style

Key Features: Bold colors, mixed patterns, and global influences.

Recommended Stones:

- Mosaic Tiles (Moroccan, Terrazzo): Vibrant and textured for backsplashes.

- Semi-Precious Stones (Lapis Lazuli, Malachite): Luxe accents in countertops or decor.

- Tumbled Marble: Soft, aged look for a relaxed vibe.

Best Uses: Feature walls, tabletops, and decorative inlays.

Final Tips for Selection:

- Consider Durability: High-traffic areas need hard stones like granite or quartz.

- Maintenance: Marble requires sealing; quartz is low-maintenance.

- Lighting: Dark stones absorb light; light stones make spaces feel larger.

- Budget: Engineered quartz is cost-effective; natural stones like marble are premium.

By matching the stone to your design style, you can create a cohesive and stunning interior that reflects your personal taste while ensuring practicality. Let me know if you need specific recommendations for a project!

If you are interested in our marble/ onyx/ terrazzo stones, and want to know more information, pls email to: may@risingfortunetrading.com, or contact my WhatsApp/ WeChat: +86 18150018770