When night comes and the hustle of the city goes, do you want to find a corner to relax? A flickering candle flame paired with a warm-textured ceramic candle holder can easily create a romantic and relaxing atmosphere. When seeing the ceramic candle holder in well desined handcraft, feeling the softness of candlelight. —this is the unique romance that ceramic candlesticks bring to life.

Elevate Your Table & Space The Navy Blue Irregular Ceramic Serving Tray That Blends Art and Function

- Organic Wave Shape: The free-flowing, irregular edges break away from rigid, traditional tray designs, adding a playful to any surface.

- Deep Navy Glaze: The hand-applied blue glaze features bring you at sea enjoying delicious food

- Handcrafted Detail: Each tray is shaped and glazed by hand, so no two pieces are identical – your tray will have unique, one-of-a-kind texture and character.

Muti-Functional Beyond the Dining Table

- Entryway Organizer: Put it by your front door to hold keys, sunglasses, and jewelry, keeping organized and clean.

- Bathroom Accent: Use it to display soap dispensers, candles, or skincare products, elevating your daily self-care routine.

- Vanity Tray: Arrange your perfume bottles and makeup brushes on it for a aesthetics on your dresser.

- Coffee Table Centerpiece: Pair it with a small potted plant or a scented candle to add a rich color and texture to your living room.

Styling Tips for Every Aesthetic

- Modern Minimalist: Put with white ceramic bowls and wooden tableware on a marble dining table.

- Cozy Feeling: Underneath the serving tray is a neutral linen tablemats, make a warm, inviting feel.

- Creative Inspiring: Rustic wood decoration and modern shape serving tray put together, jump out the routine regularlly placement

Why Choose a Ceramic Serving Tray?

- Durable & Long-Lasting: Resistant to chips, scratches, and high temperatures, it’s safe for serving hot or cold food.

- Easy to Clean: Simply wipe with a dry cloth or hand wash – no special care required.

- Food-Safe: Lead-free glaze ensures it’s safe for direct contact with fruits, cheeses, and other dishes.

Final Thoughts

The Artisanal Ceramic Vase How Traditional Chinese Craft Fits Modern Home & Office Decor

1. What makes our Ceramic vase attractive?

- Craft that lasts: Fired at 1300℃, maintains the color sturdy and it is lead-free, eco-friendly, safe.

- Modern-meets-traditional glaze: The soft blue-pink gradient isn’t just a color, but also make a released atmosphere — it’s a hand-brushed layer that feels soft and fitting into minimalist shelves, sleek office desks, or cozy tea rooms.

- Dual-purpose design: It works as a flower holder or a decoration, an art collectible.

2. Where to put Ceramic vase?

- Home living room: Place it on a wooden/marble console table with fresh flowers — makes high-end atmosphere.

- Office reception area: Put it on a counter stool — it makes everyone relaxed.

- Personal workspace: Keep it on your desk— it adds a calm, released to busy workdays.

3. How to care the ceramic vase?

- Wipe clean with a soft wet cloth.

- Don’t expose it to sudden big temperature changes (e.g., hot water after cold).

- For fresh flowers, change water every 2-3 days.

4. Why ceramic vase matters in office or at home?

Wood & Stainless Steel Tableware How It Elevates Mealtime

How This Set Makes Mealtime Easier

How to Use It for Every Occasion

How to Keep It Looking New (For Years)

Why This Set Stands Out

Why the Walnut & Steel Combo Works

Why It’s More Than “Just Kitchenware”

Why This Set Turns Routine Into Ritual

Why Sintered Stone Panels Are Redefining Contemporary Architecture

In the last decade, architectural materials have quietly undergone a structural shift. What once revolved around traditional cladding systems and conventional stone formats is now increasingly defined by sintered stone panels—not as a trend, but as a response to real design and performance demands.

Architects today are not simply choosing surfaces; they are specifying systems that must perform across structure, climate, scale, and long-term maintenance. This is where sintered stone has earned its place.

Large Format Without Structural Compromise

The rise of large format sintered stone is not driven by aesthetics alone. It answers a long-standing architectural challenge: how to create visually continuous surfaces without introducing excessive joints, thickness, or structural load.

Unlike traditional stone slabs that depend heavily on substrate reinforcement, sintered stone achieves dimensional stability through its manufacturing process. Mineral particles are compacted under extreme pressure and temperature, producing slabs that remain flat, consistent, and predictable—even at architectural scale.

For designers working on façades, transit hubs, commercial podiums, or cultural buildings, this predictability simplifies detailing and reduces downstream risk during installation.

Ultra Compact Surfaces, Engineered for Real Conditions

When professionals refer to ultra compact surfaces, they are describing more than hardness. They are referring to a material category engineered to resist:

-

UV exposure without surface degradation

-

Freeze–thaw cycles in exterior environments

-

Chemical contact in public or industrial spaces

-

Thermal variation across large elevations

These characteristics are not added through coatings or treatments; they are inherent to the material body. This distinction matters in architecture, where surface failure is not a cosmetic issue—it is a liability.

Façade Design That Balances Expression and Longevity

A well-executed sintered stone facade offers architects something rare: design freedom without sacrificing performance discipline.

From ventilated façade systems to dry-hung applications, sintered stone allows for controlled thickness, precise tolerances, and consistent color behavior over time. It enables architects to design clean geometries, sharp edges, and large visual planes—without the weathering unpredictability associated with many natural materials.

This balance is why sintered stone is increasingly specified for airports, museums, high-rise podiums, and civic architecture.

Architectural Sintered Stone as a System, Not a Surface

Too often, materials are discussed as finishes. In reality, architectural sintered stone functions as part of a broader building envelope strategy.

Its compatibility with modern fixing systems, its resistance to environmental stress, and its low water absorption make it suitable for integration into high-performance façades. For architects, this means fewer compromises between concept design and execution.

In mature markets, sintered stone is no longer positioned as an alternative—it is specified deliberately, often early in the design phase.

The Role of the Sintered Stone Manufacturer

Behind every successful project is a capable sintered stone manufacturer who understands architecture, not just production.

Consistency in slab geometry, batch stability, technical documentation, and project coordination are critical at architectural scale. Manufacturers serving international projects must support designers with:

-

Technical data aligned with building codes

-

Stable production capacity for phased developments

-

Material consultation during early specification

Without this level of collaboration, even the most advanced material falls short of architectural expectations.

A Material Shaped by Architecture, Not Fashion

Sintered stone has reached its current position not through marketing, but through application. It solves problems that architects face daily—scale, durability, precision, and longevity.

As building envelopes continue to evolve toward thinner, lighter, and more performance-driven systems, sintered stone is no longer an emerging option. It is already part of the architectural vocabulary. And in many cases, it is shaping that vocabulary.

Why “Beautiful Marble” Is Often Rejected in Final Hotel Procurement

In the early stages of hotel design, marble is rarely questioned.

It appears on mood boards, renderings, and concept presentations as a visual shorthand for luxury. The veining looks dramatic, the surface feels timeless, and the material carries an immediate association with high-end hospitality.

Yet, in many international hotel projects, that same “beautiful marble” never makes it to the final procurement list.

This is not because the stone suddenly loses its appeal—but because beauty alone does not survive the transition from design intent to operational reality.

When Design Approval Meets Procurement Responsibility

The moment a hotel project moves beyond concept approval, the decision-making framework changes.

Design teams are still focused on atmosphere and guest experience. Procurement teams, however, are now accountable for risk, consistency, and long-term performance. Owners and operators are already thinking several years ahead—past opening day, past marketing photos, and into daily maintenance and future refurbishment cycles.

This shift is where visually compelling materials often encounter resistance.

In large hospitality developments, especially those spanning multiple floors or public zones, the question is no longer “Is this marble beautiful?” but “Can this material be controlled, repeated, and managed over time?”

The Problem Is Not Marble—It Is Predictability

Natural stone variation is often celebrated as authenticity. In limited, carefully curated areas, this uniqueness enhances the spatial experience.

However, when marble flooring stone for high-traffic areas is specified across expansive lobbies, corridors, or shared public spaces, that same variation becomes a liability rather than a feature.

Procurement teams raise concerns that are rarely voiced during design presentations:

-

Will future replacement slabs match the original installation?

-

Can damaged sections be repaired without visible disruption?

-

How much visual deviation is acceptable before the space feels inconsistent?

These questions are not theoretical. They come from past projects where visually stunning materials created long-term operational challenges.

The Scale Factor: Why Size Changes Everything

Marble behaves differently at different scales.

A statement wall clad in Calacatta marble slabs for luxury hotels can be spectacular because the eye expects variation. In contrast, a 1,000-square-meter lobby floor demands visual continuity. Even minor differences in tone or veining become obvious once repeated across large surfaces.

This is why large format stone slabs for hotel lobbies are often scrutinized more heavily than feature applications. Larger slabs reduce joint lines, but they also amplify inconsistencies. Once installed, there is no practical way to “blend” mismatched sections without reworking entire zones.

At this point, procurement resistance is not about cost—it is about control.

Why Engineered Alternatives Enter the Conversation

When procurement teams propose alternatives, they are rarely trying to downgrade design quality. They are attempting to reduce variables.

Engineered stone slabs for hospitality projects are increasingly evaluated not as substitutes, but as tools for predictability. Their controlled manufacturing process offers:

-

Repeatable patterns across production batches

-

Stable color tone over time

-

Easier future replacement planning

For high-traffic or large-scale applications, these attributes often outweigh the emotional appeal of natural variation.

This is particularly true in international hotel chains, where brand consistency across properties matters as much as individual design expression.

The Unspoken Risk: Maintenance Responsibility

One of the least discussed factors in stone selection is what happens after handover.

Marble is sensitive to acids, abrasion, and cleaning methods. In a controlled residential environment, this is manageable. In a busy hotel lobby with unpredictable foot traffic, luggage wheels, and cleaning schedules, the risk increases significantly.

This is why artificial marble for commercial interiors frequently appears in final specifications—even when natural stone was initially preferred.

The decision is rarely emotional. It is operational.

Architects and Procurement Teams Are Solving Different Problems

This tension does not exist because one side is “wrong.” It exists because they are solving different problems under different constraints.

Architects are tasked with creating memorable spaces. Procurement teams are tasked with ensuring that materials perform consistently across time, geography, and operational cycles.

The most successful projects acknowledge this early and adjust material strategy accordingly.

Instead of forcing a single material everywhere, they assign stone types based on performance context—allowing each material to do what it does best.

Where Hybrid Strategies Succeed

In many contemporary hospitality projects, the final solution is not a compromise but a layered strategy.

Natural marble is reserved for areas where its uniqueness adds experiential value. Engineered materials are used where repetition, durability, and future maintenance matter more.

This approach allows design intent to survive procurement scrutiny without sacrificing long-term practicality.

Suppliers offering custom stone solutions for international hotel projects often play a critical role here—not by pushing a particular product, but by helping teams anticipate these trade-offs before they become conflicts.

Why “Rejected” Does Not Mean “Failed”

When marble is removed from a specification, it is rarely a rejection of the material itself. It is a recognition that certain environments demand predictability over individuality.

Understanding this distinction changes the conversation.

Stone selection in hospitality is not about choosing the most impressive sample. It is about choosing the material that aligns with how the space will actually be used, maintained, and perceived over time.

Projects that respect this reality early tend to avoid last-minute redesigns, budget strain, and post-opening regret.

Final Perspective

In hotel projects, beauty is necessary—but it is never sufficient on its own.

The materials that survive final procurement are those that balance design ambition with operational logic. Recognizing why certain marbles are reconsidered does not diminish their value; it places them where they belong.

Given that remaining balance, informed decisions are made—and the project is stronger for it.

Natural Marble vs Engineered Stone How Luxury Hotels Actually Decide

In luxury hospitality projects, the decision between natural marble and engineered stone is rarely as straightforward as it appears in early design concepts.

What begins as a purely aesthetic discussion often becomes a complex negotiation between design intent, procurement risk, long-term maintenance responsibility, and brand positioning. By the time a hotel project reaches final material approval, the question is no longer “Which stone looks better?” but “Which stone will still perform—and justify itself—five or ten years after opening?”

This is where many initial material preferences quietly change.

The Misconception: “Luxury Hotels Always Prefer Natural Marble”

At concept stage, natural marble dominates mood boards. Its visual depth, irregular veining, and historical association with luxury make it an intuitive choice for designers aiming to signal prestige.

However, in projects above the four-star level, marble is rarely approved for aesthetics alone.

In practice, hotel developers and operators evaluate stone through a broader lens:

-

How predictable is the material across large surface areas?

-

How difficult is it to replace damaged sections years later?

-

Who carries the maintenance burden after handover?

-

Will visual variation strengthen the brand—or undermine consistency?

Once these questions surface, the conversation shifts.

How Architects, Procurement Teams, and Owners See Stone Differently

One reason stone selection becomes contentious is that each stakeholder evaluates materials through a different risk framework.

Architects prioritize:

-

Visual continuity across public spaces

-

Natural variation as a design feature

-

Material authenticity

Procurement teams focus on:

-

Batch consistency

-

Lead time reliability

-

Replacement availability years after installation

Owners and operators ultimately care about:

-

Lifecycle cost

-

Maintenance frequency

-

Brand perception over time, not just opening day

Natural marble and engineered stone perform very differently across these dimensions.

Where Natural Marble Truly Excels

Natural marble remains unmatched in certain contexts:

-

Signature areas such as feature walls, reception desks, or statement staircases

-

Boutique or low-traffic luxury environments

-

Projects where natural variation is intentionally celebrated

In these applications, the uniqueness of marble adds value rather than risk.

However, problems arise when marble is specified across large, highly visible, high-traffic surfaces—particularly in international hotel projects where future replacement stone must match earlier installations.

The Reality of Consistency and Replacement

One of the most underestimated challenges with natural stone is long-term consistency.

Even within the same quarry, blocks extracted years apart rarely match perfectly. For hotels operating at scale, this becomes a practical concern:

-

A damaged floor section cannot always be replaced invisibly.

-

Renovation phases may introduce visible inconsistencies.

-

Maintenance decisions made years later affect brand perception.

Engineered stone addresses this issue by design.

Its controlled manufacturing process allows for:

-

Repeatable patterns

-

Predictable color tone

-

Long-term availability for future refurbishment

This predictability is one reason engineered stone increasingly appears in corridors, guestrooms, and expansive lobby flooring—areas where visual continuity outweighs material romance.

Engineered Stone Is Not a “Second Choice”

A common assumption is that engineered stone is chosen to reduce cost. In reality, many luxury hotels select it to reduce uncertainty.

When properly specified, engineered stone offers:

-

Stable performance in high-traffic areas

-

Lower maintenance sensitivity

-

Easier long-term planning for renovations

This does not diminish the role of natural stone—it reframes it.

The most successful hospitality projects today do not choose between natural and engineered stone. They assign each material to the environment where it performs best.

The Decision Logic That Actually Works

In practice, luxury hotels tend to follow a hybrid logic:

-

Natural marble for focal areas where uniqueness enhances experience

-

Engineered stone for expansive surfaces where consistency and durability matter more

-

Early supplier involvement to anticipate sourcing and maintenance implications

Projects that apply this logic early avoid late-stage redesigns, budget tension, and post-opening regret.

Why Supplier Experience Changes the Outcome

Material decisions rarely fail because of stone quality alone. They fail because trade-offs were not understood early enough.

Suppliers with experience across both natural and engineered stone categories tend to identify these issues before they become problems—often during specification rather than procurement.

At that stage, the value of expertise is not measured in square meters supplied, but in decisions avoided.

Thought in the end

In luxury hospitality, stone is not just a surface. It is a long-term commitment that affects operations, brand consistency, and guest perception for years.

Understanding how hotels actually decide—rather than how they wish to decide—makes all the difference.

Al2O3 Enabling High-Tech Applications with Precision and Reliability

Advanced Aluminum Oxide (Al2O3): Enabling High-Tech Applications with Precision and Reliability

Abstract

Aluminum oxide(Al2O3), commonly known as alumina, is a versatile and high-performance ceramic material widely utilized across numerous advanced industries due to its exceptional dielectric strength, thermal stability, chemical inertness, and mechanical hardness. This paper outlines the key properties, applications, and technical specifications of high-purity alumina, with a focus on its critical role in semiconductor packaging and lithium-ion battery coatings. Additionally, it highlights the manufacturing and supply capabilities of UrbanMines Tech., a leading Chinese producer committed to quality, customization, and reliable export services.

1. Introduction

Alumina is not merely a raw material for aluminum production; it is a cornerstone of modern high-technology manufacturing. From microelectronics and energy storage to optics, catalysis, and protective coatings, alumina’s unique combination of properties makes it indispensable. With the growing demand for miniaturization, energy efficiency, and high reliability in electronic and energy systems, the need for precisely engineered high-purity alumina has never been greater.

2. Material Properties and Specifications

High-purity alumina is categorized by its phase, purity level, particle size distribution, and trace impurity content, each parameter tailored to specific application requirements.

2.1 Purity and Impurity Control

- High-Purity Grades: 4N (99.99%), 5N (99.999%), and 6N (99.9999%) alumina are essential for sensitive applications such as semiconductor encapsulation and optical components.

- Low Alpha-Ray Emission: Critical for semiconductor packaging to prevent soft errors in memory devices. Specifications often require Uranium (U) and Thorium (Th) content below 3 ppb, with minimal Fe, Na, and Cl impurities.

- Example Specification:

- Al₂O₃ content: ≥ 99.7%

- SiO₂: < 0.15%, Fe₂O₃: < 0.1%, Na₂O: < 0.1%

- Moisture: < 0.1%, Loss on ignition: < 0.1%

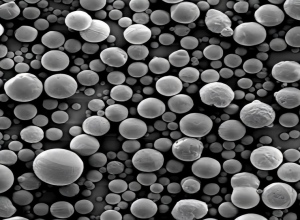

2.2 Particle Size and Morphology

Applications dictate precise granulometry:

- Spherical Alumina: D50 sizes ranging from 1 µm to 45 µm (e.g., 2.8 µm, 5.8 µm for optimized packing density in semiconductors).

- Non-Spherical Alumina: D50 from 1.5–10.5 µm, used in coatings and composites where specific surface area and green density are crucial.

- BET Surface Area: Typically < 1.5 m²/g for coatings to ensure proper slurry formulation and adhesion.

2.3 Phase and Crystalline Structure

Alpha-phase alumina (α-Al2O3) is the most thermodynamically stable form, offering superior hardness, thermal conductivity, and electrical insulation. Crystal sizes of 2–3 µm are often specified for consistent sintering behavior and final microstructure.

3. Key Applications in High-Tech Industries

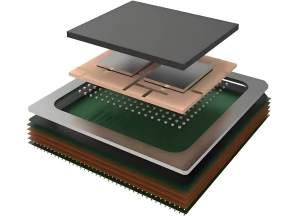

3.1 Semiconductor Packaging

Low-alpha spherical alumina is used as a filler in epoxy molding compounds (EMCs) to enhance thermal conductivity, reduce coefficient of thermal expansion (CTE), and provide radiation shielding. Particle size distribution (e.g., bimodal 2.8 µm and 5.8 µm) is optimized for maximum packing and minimal viscosity.

3.2 Lithium-Ion Battery Separator Coatings

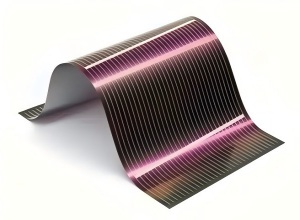

High-purity α-alumina (D50 < 4 µm) is applied as a ceramic coating on polymer separators. It improves thermal stability, prevents dendrite penetration, and enhances electrolyte wettability, thereby increasing battery safety and cycle life. The material is mixed with binders to form a stable slurry for uniform coating.

3.3 Other Advanced Uses

- Capacitors: As a dielectric barrier due to its wide band gap.

- Catalysis & Adsorption: High-surface-area alumina as catalyst support or desiccant.

- Structural Ceramics: In wear-resistant coatings, biomedical implants (e.g., hip replacements), and armor systems.

- Polishing & Abrasives: Ultrafine alumina (Diamantine) for precision polishing in optics and watchmaking.

- High-Temperature Insulation: As refractory linings in furnaces.

4. UrbanMines Tech.: A Reliable Partner from China

As global demand for specialty alumina grows, UrbanMines Tech. stands out as a trusted supplier with deep technical expertise and a customer-focused approach.

4.1 Manufacturing Excellence

- Our dedicated production lines in inland China are equipped to produce high-purity, low-alpha alumina with strict quality control.

- We offer flexible batch sizes—from R&D samples to full-scale production—ensuring short lead times and just-in-time supply.

4.2 Customization Capability

- We tailor purity, particle size distribution, morphology (spherical/non-spherical), and impurity profiles to meet exact customer requirements.

- Technical support is provided to assist with material selection and integration.

4.3 Proven Reliability and Export Expertise

- With 16 years of industry experience, we have built long-term relationships; over 60% of our clients have been partners for more than 5 years.

- We hold all necessary export licenses, including those for rare earth-related products, ensuring smooth and compliant international logistics.

4.4 The Advantage of “Made in China”

- China’s mature industrial ecosystem offers competitive advantages in raw material sourcing, advanced processing technologies, and scalable production.

- UrbanMines Tech. leverages these strengths while adhering to international quality standards (ISO, RoHS, REACH).

5. Conclusion

High-purity aluminum oxide is a critical enabler of innovation in electronics, energy storage, and advanced ceramics. Meeting the stringent requirements of modern applications demands not only advanced material science but also a reliable and agile supply chain. UrbanMines Tech. combines high-performance product offerings with responsive customization and dependable export services, making it an ideal partner for global clients seeking quality alumina solutions.

When Color Meets Eternity Is the Rise of Colored Marble Disrupting Traditional Color Aesthetics?

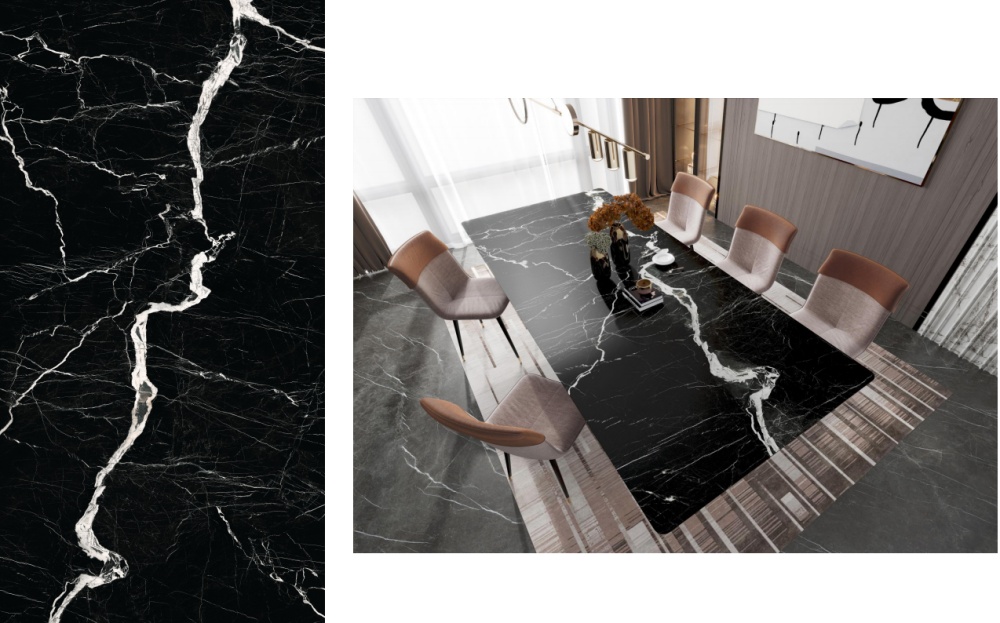

Marble, a timeless classic, has never faded from the world of design and architecture. The combination of black and white marble, with its clean lines, has long created spaces that are comfortable, natural, and sophisticated. Yet, a new trend is quietly emerging—Colored Marble Stone—infusing spaces with unprecedented vibrancy and emotional depth through its bright, saturated tones. This leads us to wonder: is it reshaping our traditional color aesthetics?

From eternal tranquility to contemporary boldness, colored marble does not replace the classic but expands the expressive boundaries of stone. It liberates spaces from the dialogue of neutral tones, granting them a richer emotional language.

Colored Marble Application Cases: Integrating Natural Beauty into Life

1. A Staircase of Hues: In a collaborative work by architect Alan Shulman and designer Frank de Biasi, a marble staircase becomes the focal point. Its treads are clad in panels of various brightly colored stones, including vibrant Colored Marble Stone, resembling a solidified rainbow that connects not only different spaces but also tradition and innovation.

2. An Artistic Focus in the Kitchen: In a New York apartment, designers from LeWhit eschewed a conventional backsplash in favor of gray breccia Capraia marble with burgundy speckles. This distinctive Colored Marble Stone wall instantly elevates the kitchen into a large-scale art piece, showcasing the dramatic appeal of natural stone veining.

3. A Colorful Manifesto in Milan: At Milan Design Week, the collaborative project between SolidNature and OMA design studio served as a grand celebration of colored marble's beauty. Particularly noteworthy was a series of marble furniture pieces designed by architects Ellen van Loon and Giulio Margheri. Even more stunning was an installation featuring nine different types of Colored ONYX Marble, their gentle glow resembling a gateway to a natural wonderland or another dimension, highlighting the stone's innate spirituality.

4.A Gravity-Defying Cabinet: A cleverly designed marble cabinet perfectly illustrates the balance between function and art. Constructed primarily from green marble with Colored Marble Stone shelves, this Marble Wall Cabinet rests on a rotating pivot. Its substantial upper mass appears to "float" precariously yet precisely on a minimal base, challenging visual perception while remaining fully functional. Designer Sabine Marcelis explored the "delicate balance between aesthetics, material, form language, and function" through this piece.

Behind the Trend: A Deep Longing for Nature and Permanence

Since the pandemic, there has been a profound yearning to reconnect with nature. This trend manifests in design as a shift: designers no longer merely adjust natural materials to fit a chosen concept or style. Instead, they use these materials as the core inspiration, building entire spatial narratives around them. Colored marble is the perfect vessel for this philosophy.

Designers and their clients cherish marble not only for its visual beauty but for the sense of permanence it carries—a connection to the deep history of the earth itself. It transcends fleeting trends, embodying true, lasting durability. Whether laying down a stunning Colored Marble Floor or crafting a unique feature wall with Colored Jade Marble, it reminds us that the most moving designs often stem from the unadulterated splendor and power of nature itself.

The rise of colored marble is not a disruption, but a renewal. It invites us to rediscover the infinite possibilities of natural materials with a more open and perceptive eye, allowing the classic to stride into the next eternity, blossoming with color.

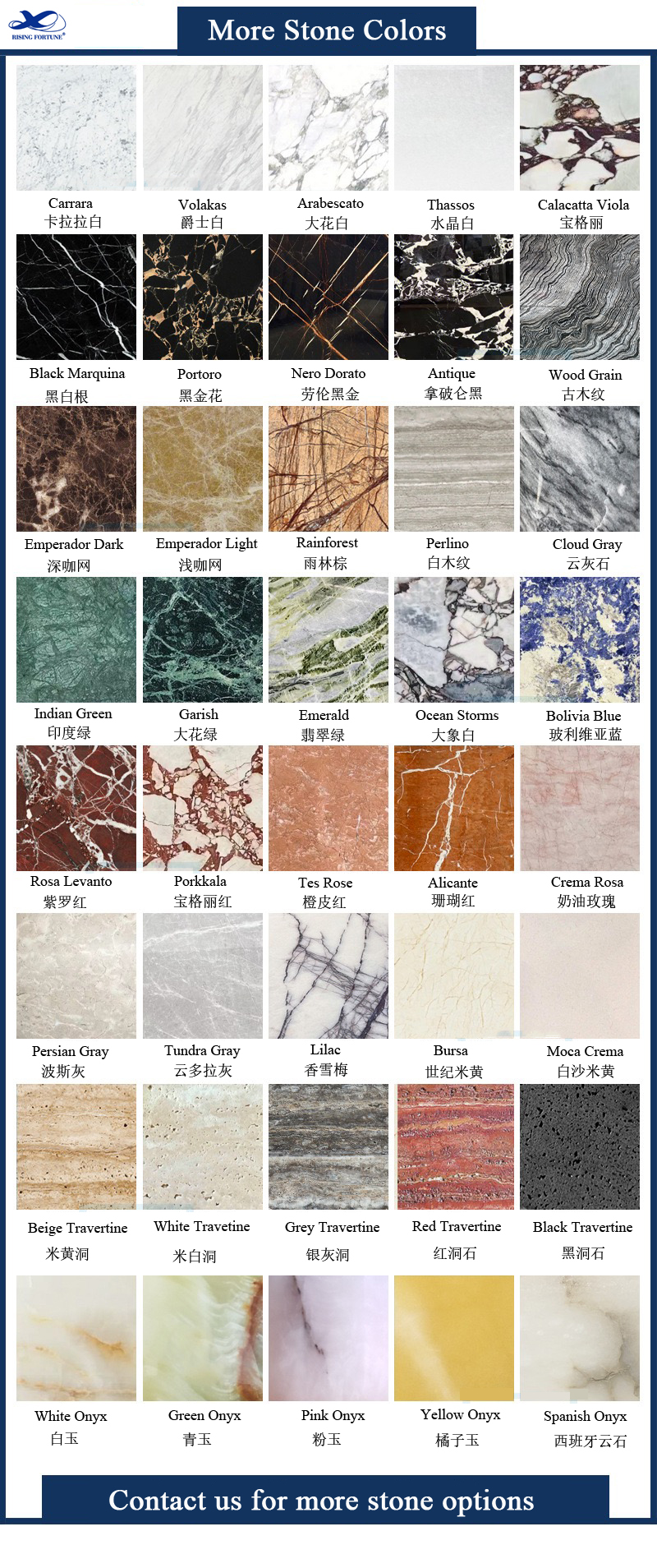

Finally, let me recommend some of the stone materials :

|

|

|

| Verde Ming Green Marble | Pink onyx | Arabescato Orobico Rosso Red Light Marble |

|

|

|

| ROSA NORVEGIA Marble | Cold Emerald Marble | Cloudy Wave Marble |

Using Stone Sinks When Designing a Bathroom

Stone basins prove great in unique bathroom design

When designing a bathroom there are a few things we need to consider. First of all, you should decide between modern and classic interior design. Having done that, it’s time to think about overall image of bathroom interior. For those of you after luxurious, natural and unique look of the bathroom, RF offers a great range of stone sinks, stone basins, stone baths and stone tiles, altogether creating a complete solution for bathroom design.

Why choose stone sinks over ceramic sinks?

That’s a question some of you are going to ask anyways, so let’s focus on that for now. Some say stone basins are very expensive and intended for rich people with too much money to throw around. Well they couldn’t be more wrong! Truth is, stone sinks are practically priced the same as good quality ceramic sinks, with the advantage of being more durable and original. The very reason behind choosing a wash basin made of natural stone over a ceramic one is their uniqueness. They are in most cases one of the kind, as they are made from natural material as found in mother nature, a piece of rock given shape. Additionally, they are number one choice if you are looking for something to make your bathroom really stand out, that is look different than traditional bathrooms with white ceramic sinks and ceramic tiles seen everywhere. If you truly want your bathroom to be original, stone tiles, pebble tiles and stone sinks are your best bet.

Will stone sinks fit into any bathroom design?

The beauty of natural stone is that it fits in any design, be it classic or modern. Stone sinks and stone tiles, as well as marble tiles and pebble tiles will fit perfectly into any existing bathroom regardless of its design. But to bring out the real beauty of them the bathroom could be designed from scratch including stone tiles or pebble tiles on walls and floor as well as stone sink and maybe a touch of wood here and there. It has proved to be great mix on numerous occasions and all of our clients are extremely happy with their luxurious bathrooms, each of which is one of a kind.